PEX MANIFOLD SYSTEM CRACK

Ultraviolet rays cause PEX to break down quickly-tubing left outdoors can harden and crack within a couple of months. PEX can be connected to existing metal supply lines with the correct fittings.Color-coding (red and blue) make it simple to distinguish hot and cold supply lines.Water flows silently through PEX, eliminating the “water hammer” noise associated with metal piping.PEX does not corrode, which can happen with both copper and steel pipes, leading to leaks and contamination of the water supply.PEX expands, making it more resistant to freeze-cracking than either copper or steel.Installing PEX does not require soldering as does copper and galvanized steel.Photo: Benefits and Drawbacksīeyond flexibility, PEX has other advantages-and two main considerations. PEX pipe remains popular for radiant floor heating. The new plastic, fashioned into flexible PEX pipe (also known as PEX tubing), arrived in the US in the 1980s, initially for radiant floor heating systems: The flexible tubing is embedded in a concrete slab and hot water pumped through to heat the slab and radiate heat to rest of the room. In 1968, German scientist Thomas Engle discovered a way to crosslink common plastic (polyethylene) through radiation to produce a much suppler form of the material. Read on to learn more about PEX-what it is, where it can be used, and all the pros and cons of this popular plumbing material. You’ve probably seen rolls of blue and red PEX pipe in the plumbing aisle of your local home improvement store, but might not know that this colorful tubing now makes it possible for enthusiastic DIYers to replace their own leaky water lines instead of calling a pro. It also help avoid unwanted leaks as they do not need to assemble manifolds on site by sweating parts to custom make a manifold.Cross-linked polyethylene (PEX), a type of flexible plastic, is currently replacing traditional copper and galvanized steel as water supply lines in both new construction and remodeling projects.

PEX MANIFOLD SYSTEM INSTALL

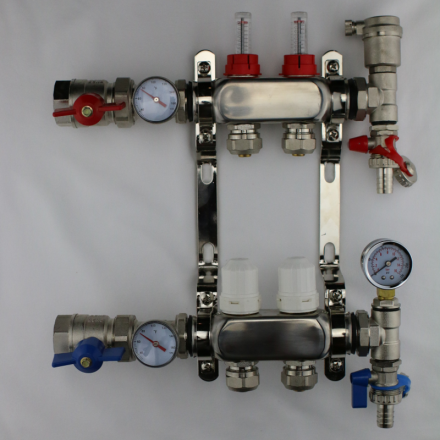

Preassembled manufactured manifolds are the preferred choice by a lot of installers as it saves a lot of install time and money. Using centrally and strategically located manifolds minimizes the total linear footage of pipes used and makes for a more efficient design of the plumbing system.

Plumbing systems use manifolds to distribute hot or cold potable water from a central location to various fixture throughout the home. Consult your radiant heating specialist to determine which is the best type for your application, if you do not have one, call us and we can discuss your project in detail. Single Zone, Multi-zone, Manually Controlled, Actuator Controlled, with and without isolation valve for each port, with and without flow meters on each port, temperature gauges, purge valves, air vents etc. There are numerous types of manifold and accessories for radiant heating and it is best to educate the difference among all of them to determine which is best for your application. Radiant Heating uses manifolds as a main central hub where the PEX lines begin and end for each loop. Manifolds are used as a main distribution center usually from a larger supply line to multiple smaller sized PEX lines.

0 kommentar(er)

0 kommentar(er)